Info

At Publishing Xpress, we specialize in printing multipage documents from 8 pages to over 600 pages for a wide range of clients, including companies, individuals, nonprofit organizations, and schools. We print a large assortment of products, including books, catalogs, art books, annual reports, association directories, calendars, children’s books, church directories, college journals, college textbooks, yearbooks, comic books, convention workbooks, cookbooks, family history books, journals, magazines, literary magazines, manuals, membership directors, memory books, newsletters, motivational books, novels, photo books, poetry books, product manuals, program booklets, seminar workbooks, souvenir books, special event fundraising booklets, team sports books, training manuals, and workbooks.

Please check out our Book Printing Ideas page for more information. With our numerous options, including four standard finished sizes and any number of custom sizes, four binding styles, many paper choices, lamination on covers, fast turnaround, and low printing prices, we hope you’ll consider Publishing Xpress for your next printing project.

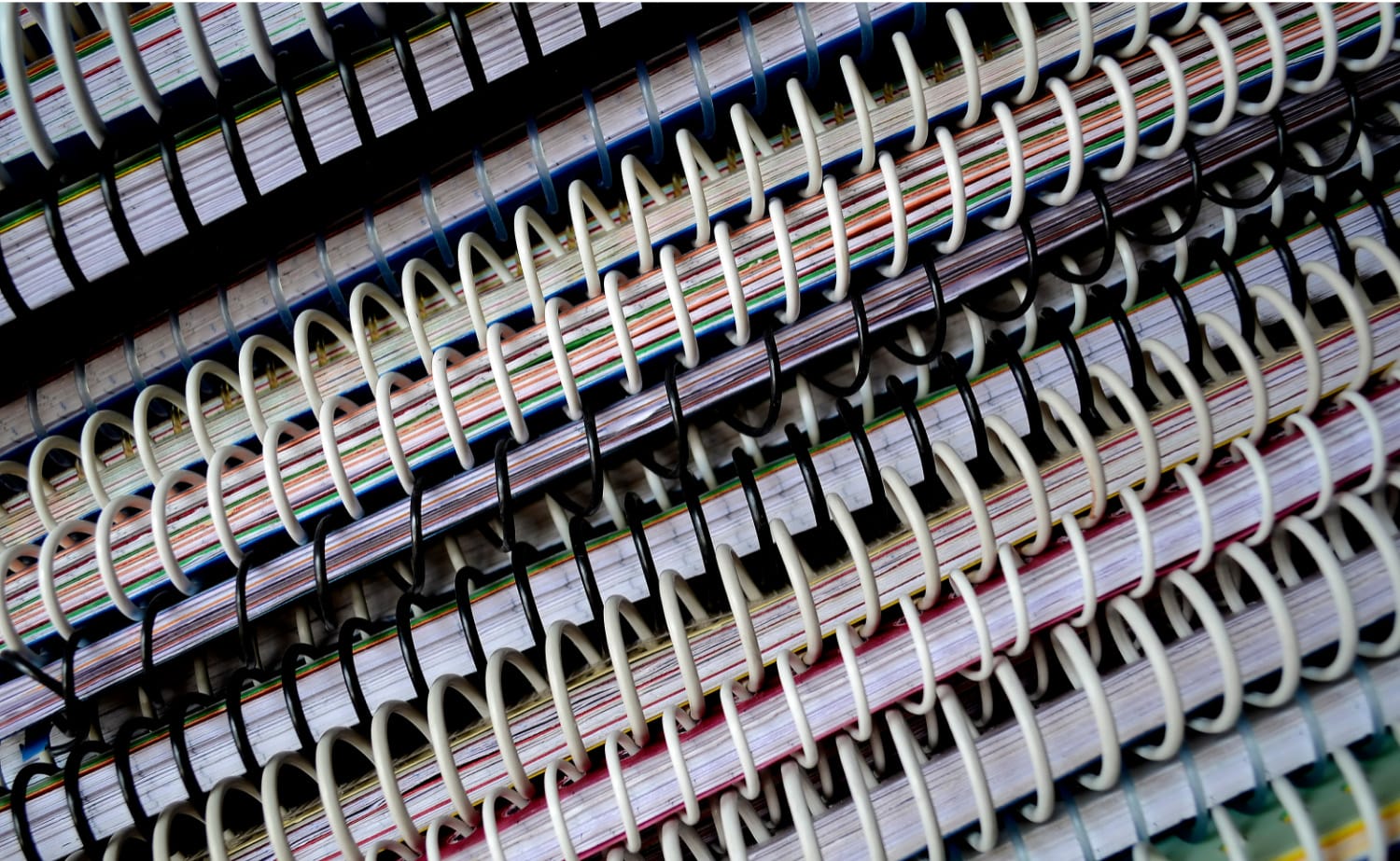

Effortless Plastic Coil Printing for High-Quality Booklets

Need a durable and flexible binding solution for your booklets? Plastic coil printing could be the answer. With robust plastic coils, this binding method allows your pages to lay flat and rotate 360 degrees. Read on to explore the benefits, applications, and tips for successful plastic coil printing.

Key Takeaways

- Plastic coil binding provides durability, flexibility, and a full 360-degree rotation, making it ideal for frequently used documents like booklets and manuals.

- Choosing the right paper stock and designing with attention to detail enhances the professional look and durability of plastic coil bound booklets.

- The production process emphasizes competitive pricing, quality assurance, and strong customer support to ensure a smooth printing experience.

Understanding Plastic Coil Binding

Plastic coil binding, also known as spiral binding, is a popular method for securing pages together using durable plastic coils. Unlike wire-o binding or perfect binding, plastic coil binding offers a unique blend of durability and flexibility. The coils are made from resilient plastic, resistant to bending and breaking, making them ideal for frequently used documents.

One of the standout features of plastic coil binding is its ability to support a full 360-degree rotation. This means that pages can be flipped and folded back on themselves, making it incredibly easy to read and reference information. Whether you’re working on a manual, a report, or a high-quality booklet, plastic coils provide a reliable and professional binding solution.

These coils are not just practical but also aesthetically pleasing. Available in various colors, they can enhance the visual appeal of your booklets, ensuring they look as good as they perform.

Benefits of Plastic Coil Bound Books

Numerous benefits make plastic coil binding a preferred choice for a wide range of documents. One of the primary advantages is that it allows pages to lay flat when open, enhancing readability and usability. This feature is particularly beneficial for manuals and presentations, where ease of reference is crucial.

Another significant benefit is the 360-degree rotation capability, making it easy to flip through pages without damaging the binding. This is especially useful for cookbooks, which need to stay open while cooking. Additionally, the durability of plastic coils ensures that your booklets can withstand frequent use without distortion.

Coil bound books also offer a professional appearance, making them suitable for reports, marketing materials, and high-use documents like training manuals and reports. The availability of multiple coil diameters means that you can accommodate various book thicknesses, ensuring a perfect fit for your project.

Plastic coils come in a range of colors, allowing you to match them with your booklet’s design for an added touch of customization. Whether you’re creating magazines, booklets, or other printed materials, plastic coil binding offers a versatile and durable solution.

Applications of Plastic Coil Binding

The versatility of plastic coil binding makes it suitable for a wide array of projects. From books and reports to manuals and cookbooks, this binding method can handle them all. The durability and flexibility of plastic coils make them ideal for training materials and presentations, which are often handled frequently.

Travel guides are another popular application for coil binding, as the 360-degree rotation allows users to easily flip through pages and reference information on the go. Similarly, calendars and planners benefit from coil binding because they can lay flat against surfaces, making them easier to use.

Businesses needing quick turnaround times benefit significantly from plastic coil binding. It supports short production runs, making it ideal for projects like 200 books that need to be completed swiftly. Whether you’re working on saddle stitched booklets, perfect binding projects, or simply want a reliable binding style, plastic coil binding has you covered.

Choosing the Right Paper Stocks

Selecting the right paper stocks is crucial for the success of your plastic coil bound booklets. The weight of the paper plays a significant role in the overall durability and feel of the booklet. Heavier stock generally offers a more premium feel and is better suited for high-quality printed materials.

In addition to weight, the texture of the paper can greatly enhance the aesthetic appeal of your booklet. Options like linen or smooth finishes can cater to specific design goals, adding a unique touch to your project. Finishing options, such as gloss or matte lamination, not only protect the surface of the booklet but also affect how colors appear on the paper.

Choosing high-quality paper stocks ensures that your booklets maintain a professional image and meet customer expectations. Whether you’re printing manuals, reports, or custom-sized booklets, the right paper type can make all the difference.

Designing Your Plastic Coil Booklet

Designing a plastic coil booklet involves careful planning and attention to detail. Utilizing graphic design software like Adobe InDesign or Canva can help you create visually appealing layouts tailored for coil binding. One important aspect of design is to include a bleed area of 0.125 inches to prevent unprinted edges after cutting. Ensure that all important content is kept within safe margins to avoid any trimming issues. High-resolution images are essential for maintaining print quality and clarity in your booklet design. Focusing on creating an engaging layout can significantly enhance the visual appeal of your plastic coil booklet.

Consider the design elements for the front cover, back cover, and inside pages. Each of these components plays a critical role in the overall look of your booklet. From custom sizes to full-color prints, every detail matters in creating a professional and attractive final product.

Providing Project Specifications

When specifying a project for coil binding, it’s crucial to provide a complete list of details. This includes the page count, any specific binding style requested, and cover options. Clear communication of these details helps ensure that the final product meets your expectations.

Custom sizes for coil-bound projects can be accommodated, but they must be specified upfront to avoid discrepancies. Whether you need a gloss finish or a particular paper type, detailing all specifications in advance is key to a successful project.

Uploading Your Files

Uploading your files correctly is a critical step in the printing process. It’s essential to understand the specific file requirements of the printing service, including dimensions, color modes, resolution, and bleed settings. Using PDF format is preferred as it preserves design integrity and is compatible with most printing software.

Ensure that your documents are correctly set up with attention to dimensions and color mode, ideally utilizing CMYK for accurate color reproduction. High-resolution images of at least 300 DPI are crucial for achieving sharp and clear prints. Outlining fonts before uploading can help prevent font-related issues during printing by converting text into vector shapes.

Packaging all necessary files, including fonts and images, into a single folder facilitates easy access for the printer. Organize your PDF pages in the correct order before uploading to ensure a smooth printing process.

Proofing and Approval Process

The proofing and approval process is an essential step to ensure the quality of your printed documents. Thoroughly reviewing proof copies and pdf proof before printing helps catch any errors or discrepancies that may affect the final output. Common preflight issues include fonts not being embedded, low-resolution images, and the absence of bleed, which can lead to printing problems.

Digital proof comparison tools can help identify any variations in colors, text, or layouts between the proof and the approved artwork. Annotations can be added to digital proofs for clarity, aiding in the feedback loop during the approval process. Customers can access a virtual preview of their prints, which aids in maintaining quality assurance before final production.

Providing clear instructions with specific requirements for the printing job can help ensure that the final product meets expectations. This step-by-step review process is crucial for achieving a professional finish and avoiding costly mistakes.

Production and Delivery

Once your proofs are approved, the production process begins. Deadlines are taken seriously, and the typical production time starts the day after proof approval, lasting for four to six business days. Shipping time is separate and can vary from one to five business days based on the delivery location.

Planning in advance and providing clear project specifications ensures a smooth production and delivery process. This allows you to receive your high-quality booklets on time and in perfect condition.

Competitive Pricing and Quality Assurance

One of the standout features of plastic coil printing services is the balance of competitive prices and high-quality materials. Publishing Xpress emphasizes affordable prices without sacrificing the quality of their prints. This approach guarantees customers receive excellent value for their investment.

Maintaining this balance allows for the creation of professional and durable booklets without breaking the bank. Whether you need a small run or a large batch, you can expect consistent quality and cost-effective solutions, including an accurate quote.

Customer Support and Assistance

Customer support is a cornerstone of any successful printing service. Many companies offer direct access to knowledgeable representatives without the hassle of automated systems.

Effective communication between customers and printing vendors is crucial for resolving any discrepancies found during the proofing process. With quick response times and established incident management processes, you can expect a smooth experience from start to finish.

Summary

In summary, plastic coil binding offers a versatile, durable, and professional solution for creating high-quality booklets. From understanding the basics to designing and providing project specifications, each step plays a crucial role in ensuring a successful final product.

By following this guide, you’ll be well-equipped to create booklets that not only look great but also stand the test of time. Ready to get started on your next project? Dive in and experience the benefits of plastic coil binding today.

Frequently Asked Questions

What is plastic coil binding?

Plastic coil binding is a durable binding method that uses plastic coils to secure pages, enabling complete 360-degree rotation for ease of use. This binding style offers long-lasting strength and flexibility for documents.

What are the benefits of plastic coil bound books?

Plastic coil bound books provide a durable and professional appearance, allowing them to lay flat when open, which enhances usability and accommodates various book thicknesses.

What types of projects are suitable for plastic coil binding?

Plastic coil binding is ideal for projects such as manuals, reports, cookbooks, calendars, and training materials due to its durability and flexibility. It’s an excellent choice when you need a binding method that allows the document to lay flat and facilitates easy page turning.

How do I choose the right paper stocks for my booklet?

Choose paper stocks by assessing their weight, texture, and finishing options to ensure they enhance both durability and aesthetic appeal for your booklet. This careful selection will significantly impact the final presentation.

What should I keep in mind when uploading my files for printing?

When uploading your files for printing, it’s crucial to meet the printer’s specifications, use high-resolution images, and organize your PDF pages properly to ensure quality results.